INDUSTRIAL ONCE-THROUGH STEAM

SOLID FUEL BOILERS

SOLID FUEL BOILERS

up to 30% more efficient than traditional boilers

INDUSTRIAL ONCE-THROUGH STEAM

SOLID FUEL BOILERS

SOLID FUEL BOILERS

up to 30% more efficient than traditional boilers

ADVANTAGES OF «BENT-IRON» OVER TRADITIONAL STEAM BOILERS

ADVANTAGES OF «BENT-IRON» OVER TRADITIONAL STEAM BOILERS

ADVANTAGES OF «BENT-IRON» OVER TRADITIONAL STEAM BOILERS

STEAM GENERATOR «BENT-IRON»

IDEAL SOLUTION FOR

STEAM GENERATOR «BENT-IRON»

IDEAL SOLUTION FOR

STEAM GENERATOR «BENT-IRON»

IDEAL SOLUTION FOR

Dairy and cheese production technologies are characterized by highly unstable steam demand, which can fluctuate from 30% to 100% of their capacity in just 5 minutes. This variability requires steam generation systems to have a high level of adaptability and quick response to fluctuations in production needs to ensure uninterrupted technological processes and maintain product quality. Once-through steam boilers are best suited for this task due to their low water content in the heat exchanger and the absence of large inertial components.

Steam is used in brewing processes by numerous breweries worldwide. High-quality steam ensures uniform heating and stable brewing conditions. Market leaders specifically choose once-through boilers because they provide ideal parameters for process steam and save costs through high energy efficiency.

Once-through steam boilers are considered an ideal solution for meat processing plants due to their high efficiency, rapid steam generation, and optimal energy utilization. This type of steam boiler has a low water content, allowing for instant response to the variable steam demand characteristic of the meat processing industry.

Once-through steam boilers provide rapid and efficient steam supply, crucial for precise control of moisturizing and processing in animal feed plants. These boilers have high thermal efficiency, which allows for reduced energy losses and lower operational costs. As a result, animal feed manufacturers can achieve not only high product quality but also increased profitability through cost reduction.

To produce the most delicious candies and sweets, confectionery factories require high precision in temperature regulation for thermal processing such as baking, sugar caramelization, glaze and chocolate preparation, etc.

The once-through boiler type is ideally suited for the dynamic production processes of confectionery factories due to its ability to quickly respond to changes in production needs, providing instant increase or decrease in steam supply. This allows for unprecedented accuracy in temperature control.

Steam use in this industry is critical for various technological processes, including oil extraction, refining, and deodorization, as well as for equipment sterilization. Once-through steam boilers provide quick response to changes in production needs and can effectively manage large load fluctuations. This allows enterprises to maintain constant and efficient steam supply, optimize energy consumption, and reduce energy resource costs.

In the wood processing industry, raw materials often have varying moisture levels, so the need for steam for drying, pressing, and wood processing can change significantly. A once-through boiler with rapid operating mode modulation and maintenance of steam quality indicators allows for increased technology productivity and reduces operational costs for steam generation by at least 30% compared to traditional boilers.

Precision temperature control, ensuring stable continuous operation, and ease of maintenance are the main criteria for choosing a steam boiler for an agro-industrial enterprise.

The use of once-through steam boilers in agro-industrial enterprises not only contributes to the optimization of production processes and improved product quality but also provides significant economic benefits due to efficient energy use and reduced operational costs.

Traditional steam boilers are often unable to provide an instant response to increased steam consumption or, conversely, a shutdown, leading to significant energy losses and production disruptions, undermining product quality and production efficiency.

Once-through steam boilers solve this problem, thanks to their quick start and ability to instantly regulate steam supply according to process needs. Textile enterprises can significantly increase their operational efficiency and energy efficiency.

Once-through steam boilers are a revolutionary solution for the paper and cardboard industry as they provide instant response to changes in production needs. Due to their high thermal efficiency, these boilers significantly reduce energy costs while ensuring stable and precise steam supply for drying processes and other thermal treatments. This not only improves the quality of the final product but also increases the overall productivity of the plant.

Synthesis reaction, distillation, extraction, and purification processes require adherence to precise temperature regimes and uniform heat transfer. This is crucial for the quality of the final product. Once-through steam boilers quickly ramp up and down steam production, allowing for precise maintenance of required temperature conditions while minimizing energy consumption. This allows for reduced energy costs and also contributes to increased production efficiency and product quality. Additionally, the simplicity of maintaining once-through boilers ensures low costs for their operation and upkeep, which is an important factor for enterprises striving to optimize processes.

The pharmaceutical sector encompasses the production of chemical synthesis products such as medicines, oleochemical products (food products, cosmetics), and products related to polymer production (rubber, adhesives, paints, etc.).

The production technology includes both continuous and cyclic thermal processing. Cyclic processes, in particular, can involve significant fluctuations in thermal load, from initial high demand to temperature maintenance at the end of the cycle. When using steam, this leads to wide fluctuations in steam requirements.

“Bent-Iron” steam generators fully meet these needs. Ease of maintenance and high energy efficiency reduce overall operational costs, minimizing the risks of production downtime and allowing for reduced operational expenses.

MARKET LEADERS HAVE ENTRUSTED US WITH THEIR STEAM SUPPLY

MARKET LEADERS HAVE ENTRUSTED US WITH THEIR STEAM SUPPLY

MARKET LEADERS HAVE ENTRUSTED US WITH THEIR STEAM SUPPLY

WHAT OUR CLIENTS SAY ABOUT US

ЩО ГОВОРЯТЬ ПРО НАС НАШІ КЛІЄНТИ

WHAT OUR CLIENTS SAY ABOUT US

WHAT OUR CLIENTS SAY ABOUT US

«BENT-IRON» BOILER PLANT IS A FULL–CYCLE PRODUCTION FACILITY

«BENT-IRON» BOILER PLANT IS A FULL–CYCLE PRODUCTION FACILITY

«BENT-IRON» BOILER PLANT IS A FULL–CYCLE PRODUCTION FACILITY

Watch the video and get acquainted with our production (duration 2 minutes)

700+ MANUFACTURED COILS

12+ YEARS OF EXPERIENCE

700+ MANUFACTURED COILS

12+ YEARS OF EXPERIENCE

700+ MANUFACTURED COILS

12+ YEARS OF EXPERIENCE

THE SECRET TO SAVING AT LEAST 30% on FUEL

Quick Start

Starting a steam boiler requires warm-up time, which depends on the water volume of the heat exchanger and the weight of the concrete lining. The thermal energy needed for heating is a direct loss. Once-through steam boilers have 3-4 times less water volume, and the weight of the concrete lining in Bent-Iron boilers is 5 times less than in traditional boilers. Consequently, heat losses during startup are significantly lower

No Continuous Blowdown

Continuous and periodic blowdowns from the boiler drum and other elements are an integral part of traditional boiler operation.

Bent-Iron boilers only require periodic blowdown from the steam separator. This allows for the removal of “impurities” with a highly concentrated flow, drastically reducing thermal and material losses.

8 Times Lower Losses with Irregular Consumption

In real operating conditions, steam consumption is irregular and unstable.

Traditional boilers experience significant losses during sudden load changes, especially with a sharp decrease in steam consumption. Bent-Iron steam generators, thanks to their small water volume and advanced control system, almost instantly modulate the operation of all systems and significantly reduce heat losses.

4 Times Lower Standby Losses

Most often, the need for steam is cyclical. Maintaining a traditional boiler in standby mode at “idle” consumes a significant amount of energy. A once-through steam boiler, due to its design, consumes far less energy to maintain a hot state.

У чому секрет економії мінімум 30% на паливі

THE SECRET TO SAVING AT LEAST 30% on FUEL

THE SECRET TO SAVING AT LEAST 30% on FUEL

Quick Start

Starting a steam boiler requires warm-up time, which depends on the water volume of the heat exchanger and the weight of the concrete lining. The thermal energy needed for heating is a direct loss. Once-through steam boilers have 3-4 times less water volume, and the weight of the concrete lining in Bent-Iron boilers is 5 times less than in traditional boilers. Consequently, heat losses during startup are significantly lower.

No Continuous Blowdown

Continuous and periodic blowdowns from the boiler drum and other elements are an integral part of traditional boiler operation.

Bent-Iron boilers only require periodic blowdown from the steam separator. This allows for the removal of “impurities” with a highly concentrated flow, drastically reducing thermal and material losses.

8 Times Lower Losses with Irregular Consumption

In real operating conditions, steam consumption is irregular and unstable.

Traditional boilers experience significant losses during sudden load changes, especially with a sharp decrease in steam consumption. Bent-Iron steam generators, thanks to their small water volume and advanced control system, almost instantly modulate the operation of all systems and significantly reduce heat losses.

4 Times Lower Standby Losses

Most often, the need for steam is cyclical. Maintaining a traditional boiler in standby mode at “idle” consumes a significant amount of energy. A once-through steam boiler, due to its design, consumes far less energy to maintain a hot state.

COMPLETE TESTING BEFORE SHIPMENT

COMPLETE TESTING BEFORE SHIPMENT

This operational scheme allows us to verify all systems, eliminate possible manufacturing errors, timely detect all malfunctions, and gain the ability to complete all installation work at the customer’s site in just a few days.

Before making a decision, we provide our clients with the opportunity to see the equipment in operation at facilities or in our test shop.

TECHNICAL SUPPORT AND SERVICE

TECHNICAL SUPPORT AND SERVICE

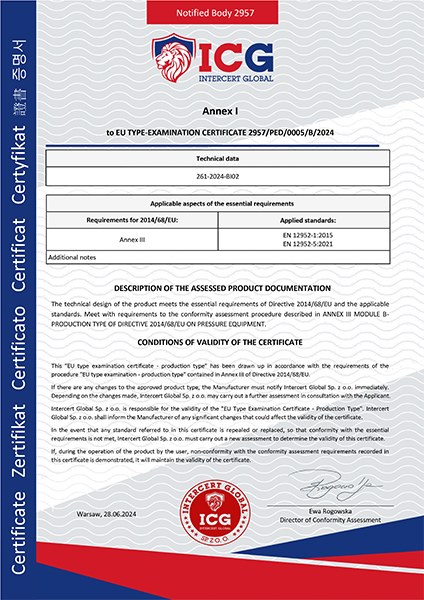

CERTIFIED IN UKRAINE AND EU

CERTIFIED IN UKRAINE AND EU

CERTIFIED IN UKRAINE AND EU